Are threaded holes adding extra cost?

Putting threads in holes (tapping) is usually not a challenging process. It does get progressively more difficult and expensive as a tapped hole gets deeper.

Specifying threads that are longer than necessary can increase the cost of parts, as special tooling may be required and there is an increased risk of tap breakage.

Contrary to popular belief, in many situations increasing the length of the threads does little to increase the strength. The thread depth of 1.5 to 3 times the diameter does most of the work in a threaded hole.

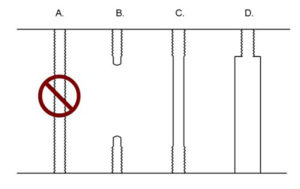

Illustration: (A) Long tapped holes require custom tooling and are expensive to make. (B) Shorter holes tapped from each side are cost effective. (C) A drilled hole through the part with shorter threads from each end is also cost effective. (D) If a long fastener or part needs to pass through the threaded hole, consider counter boring.

Questions about threaded holes?

Contact Us.